- STRATASYS DIRECT MANUFACTURING

A Glimpse Into The Future of Design Manufacturing

Rapid Prototyping, an innovative and dynamic approach to product development, that has played a vital role in revolutionizing the way in which the ideas are transformed into tangible prototypes. Involving the quick and iterative creation of physical models or prototypes using CAD (Computer-Aided Designing) Data. Rapid Prototyping allows designers, engineers and product developers to swiftly visualize and test their ideas, leading to accelerated innovation and improved outcomes of designs.

At the crossroads of Rapid Prototyping, the synergy of digital design and physical realization takes place. The journey begins with the creation of a meticulous digital 3D model, by using CAD software. This virtual blueprint serves as the foundation of the rapid prototyping process.

When to Opt for Rapid Prototyping?

Rapid prototyping brings all structurally and functionally important pieces together and makes an ideal use case that is open to redesign and changes based on feedback and suggestions.

It is ideal for situations when:

- An initial iteration of the product needs to be shown to the clientele.

- Feedback & suggestions are needed for further design improvements.

- A variety of low-cost versions of the same product in different forms need to be made.

- There is a paucity of resources for a full-scale launch.

- The functionality or compatibility of a part is to be tested.

There may be other scenarios & situations that would entail opting for rapid prototyping first before launching it in the market.

If you are still unsure whether your particular situation warrants it, connect with our leading experts now.

Breaking Barriers With Rapid Prototyping

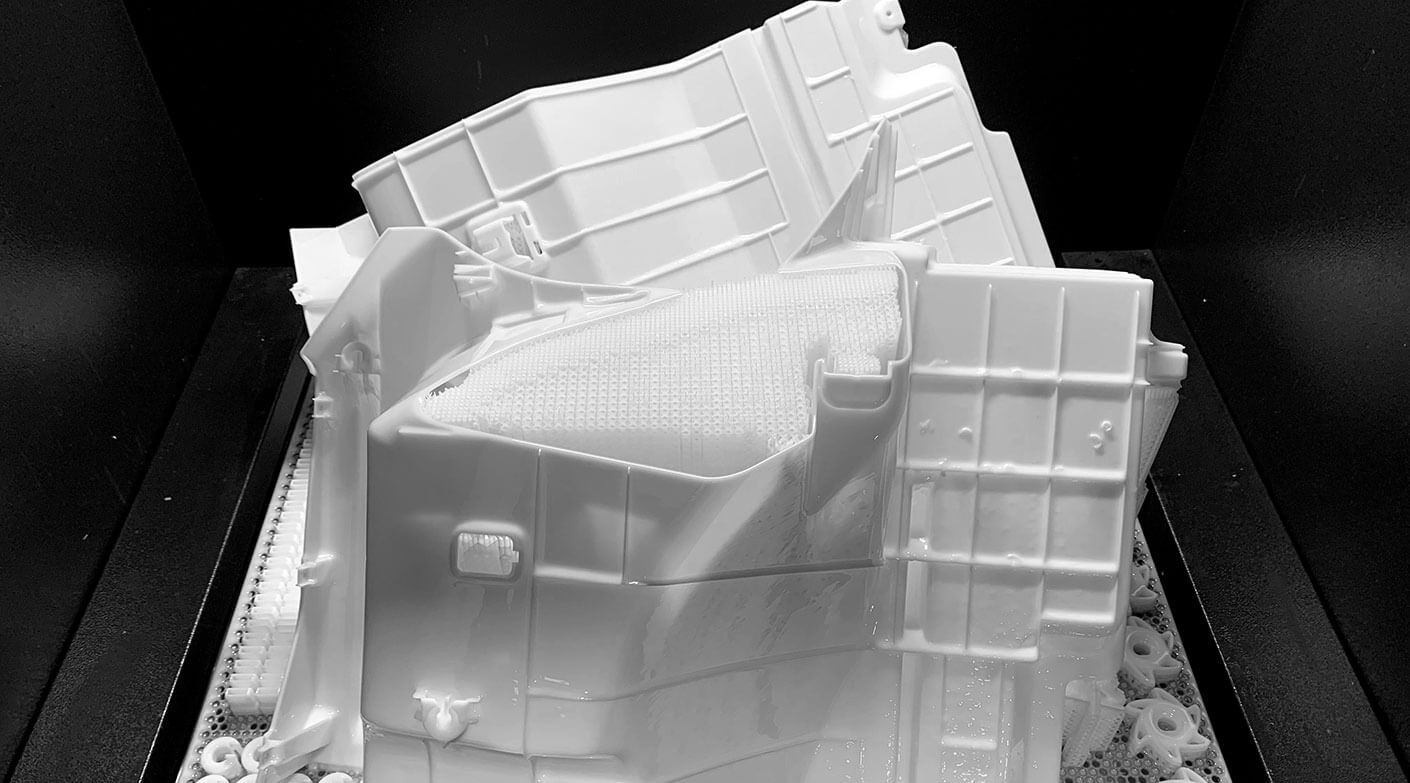

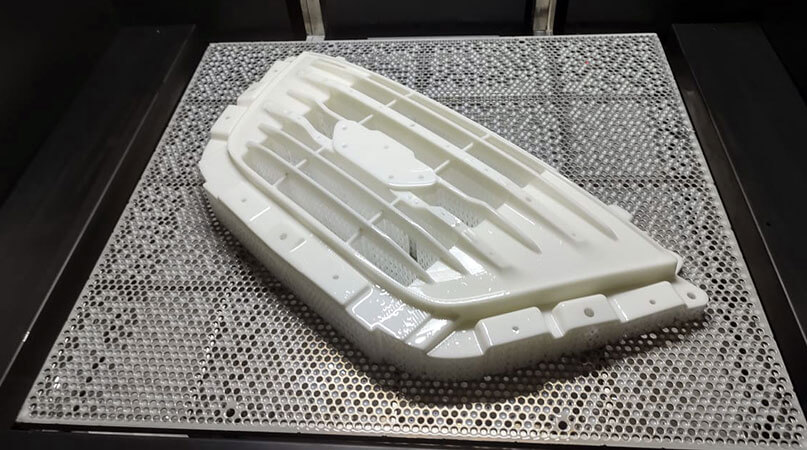

3D Printing technique

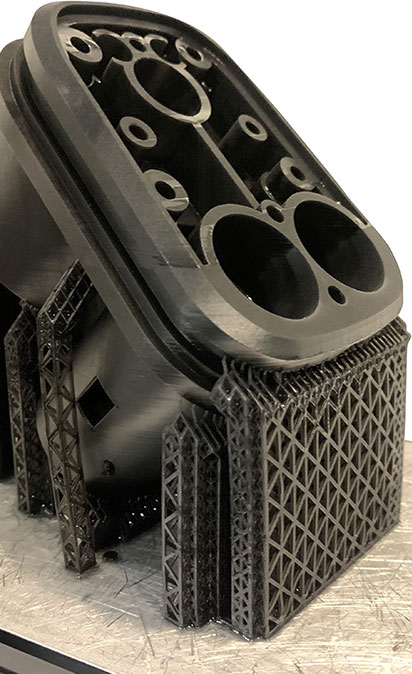

3D printing is a revolutionary technology that has transformed the manufacturing landscape. It utilizes computer-controlled machines to create three-dimensional objects layer by layer, using various materials such as plastics, metals, or alloy powders. This process enables the production of highly complex and customized designs with remarkable precision.

- Fusion Deposition Modeling (FDM)

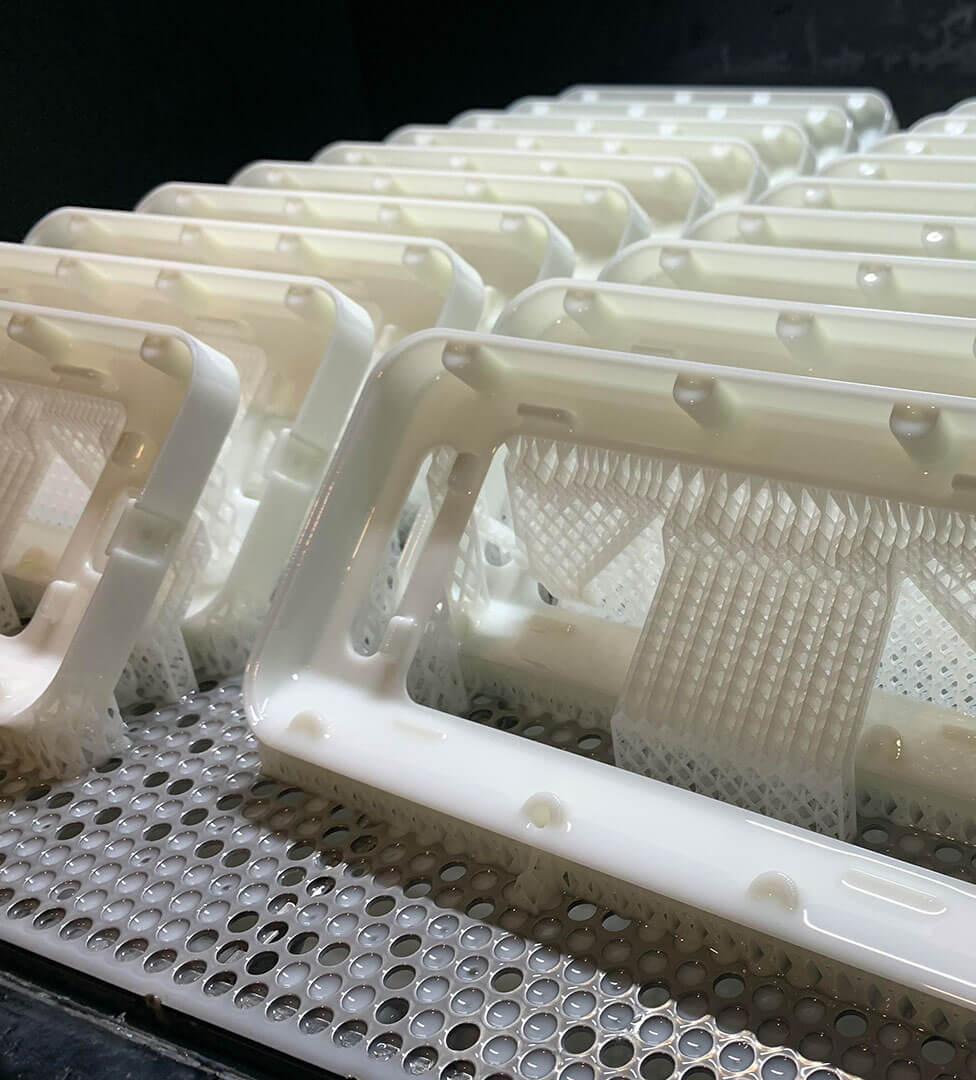

- Stereolithography (SLA)

- Selective Laser Sintering (SLS)

- Digital Light Processing (DLP-LPSC)

- Vacuum Casting (VC)

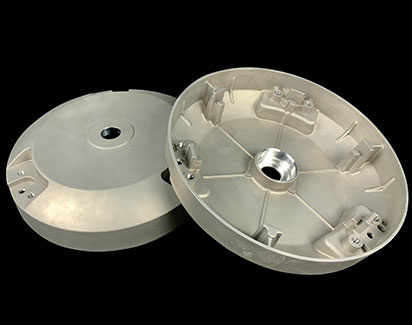

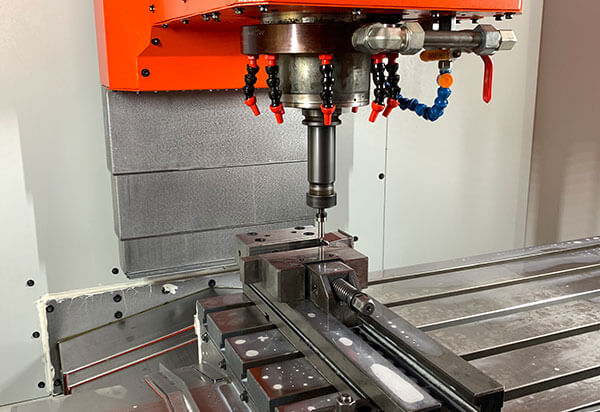

CNC Machining

CNC (Computer Numerical Control) machining is a sophisticated manufacturing technique that combines precision engineering with automation. It involves using computer-controlled machines to shape and cut materials into intricate and accurate designs.

At CubeIn, we offer CNC Machining on two types of materials:

- Metals

- Plastics

Benefits of Rapid Prototyping?

- Reduces time & costs by minimizing structural irregularities.

- Showcase & demonstrate the physical product to customers quickly.

- Market testing before a full-scale launch.

- Develop multiple variations with different structures, designs & finishes.