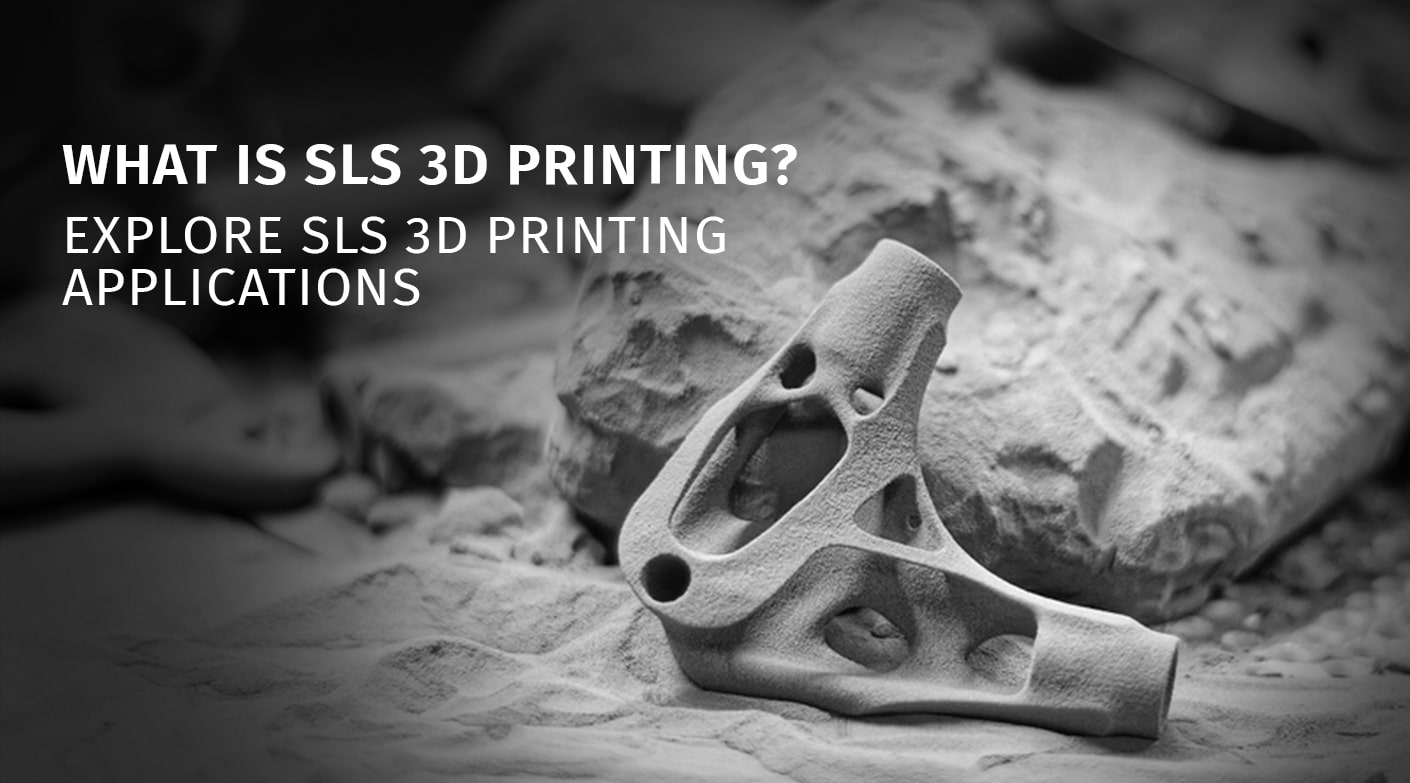

Looking for a game-changer technique to revolutionize your manufacturing? Selective Laser Sintering (SLS) is your go-to techique. SLS has emerged as an ultimate and widely used solution in the additive manufacturing industry. The industrial landscape experiences significant transformation through SLS because it enables fast prototyping, coupled with functional part manufacturing and innovative design functions. This blog explores Selective Laser Sintering 3D printing fundamentals as well as its essential business applications.

Let’s conduct an in-depth analysis of the advanced 3D printing technology, SLS, to examine its applications throughout different sectors.

Overview of SLS 3D Printing Technology

A high-powered laser drives the Selective Laser Sintering, an additive manufacturing process, and helps in the production of solid structures. This laser sinters powdered materials and binds them to create the structure. SLS initiates with slicing digital 3D data into thin sequential layers.

The SLS machine uses a powder distribution mechanism to spread a thin powdery material layer on the developed platform, before the selective laser fuses the material into shape according to the design specifications. This process continues layer-by-layer until the object solidifies and is formed fully.

How SLS 3D Printing Works?

- The top layer of the build platform is obtained from thinly distributed powder material, which generally contains nylon or polymer.

- Using Laser Sintering technology, the machine chooses particular powder particles to fuse with laser heat. The process follows the virtual design model.

- The process builds objects layer by layer when the platform descends after each application of new powder until the complete object is completed.

- After printing ends, the system proceeds to cooling down the finished object before processing it for cleaning and finishing steps.

Thus, SLS 3D printing process creates objects directly through digital models, while achieving complex shapes and minimizing material consumption, which traditional techniques are not capable of.

Key SLS 3D Printing Applications

#1 Aerospace and Automotive

The aerospace and automotive industries make use of SLS 3D printing applications for developing strong yet lightweight components. The technology enables engineers to build complex components which improve system performance and reduce fuel consumption.

- Engineers reduce weight of designs by creating lightweight components while not impacting their strength attributes.

- The process enables construction of sophisticated designs which standard manufacturing equipment cannot replicate.

- Functional prototyping enables rapid testing and iteration of parts before mass production.

#2 Industrial Manufacturing

Additive manufacturing in industry uses SLS as a key process that provides efficient production because of its versatility, and durability.

- Tooling and fixtures process in SLS 3D printing delivers economical and fast-built customized solutions for your industrial needs.

- Through spare parts manufacturing operations, the production of needed replacement components helps minimize time-based business interruptions.

- SLS provides material efficiency because it utilizes less material resources while creating designs than conventional industrial processes.

#3 Consumer Goods

The market of consumer goods and wearables has experienced a transformation through SLS 3D printing technology. With SLS, it has become easy to develop and offer customized products that maintain their durability across wearables and consumer goods, be it eyewear frames or footwear items.

- Custom fit products are developed through tailor-made designs for individual comfort and aesthetics.

- SLS technology enhances durability of materials that ensures long-lasting and high-quality end-use products.

- Through free design possibilities, manufacturers can produce complex innovation-based modern wearable products.

#4 Healthcare and Medical

The healthcare sector has experienced several improvements because of SLS 3D printing technology. The production of patient-specific solutions with the help of the technology has revolutionized medical applications.

- Medical professionals use SLS-produced precise surgical guidance platforms that resemble patient anatomy and specialized clinical instruments and help them to perform hard procedures with ease.

- SLS 3D printing develops the customized designs according to the exact specifications of the patient’s body and structures.

- Biocompatible implants are used as medical-grade materials to offer effectiveness and safety. The technology is also used for medical device fabrication, especially in orthopedic oncology (32%), orthopedics (36%), and in other surgeries as well.

#5 Education and Research

Educational institutions depend on SLS 3D printing technology to develop new solutions while delivering hands-on education to their students.

- Students along with researchers benefit from rapid prototyping because it enables them to test and refine their ideas.

- The technology operates within material science and engineering studies as part of scientific experimentation.

- The educational use of SLS printing produces cost-effective functional models.

Why Choose SLS 3D Printing Technology?

- Versatility of Materials: The SLS technology operates with different raw materials which include polymers as well as metals, ceramics, and composites.

- Scalability: SLS technology is a prototyping tool for quick development as well as production of finished products. Manufacturers can move designs directly from concept to manufacturing while cost-effectively achieving better operational efficiency.

- No Need of Support Structures: SLS has surrounding raw materials for backing during construction thus, eliminating the necessity for additional support frameworks.

- Mechanical Strength: SLS-produced parts have outstanding mechanical properties with strength, durability and impact resistance, which makes them suitable as functional prototypes and end products.

- Complex Geometries: When using SLS technology, it can fabricate hard-to-make complex geometrical components easily that traditional production methods would struggle to reproduce.

- Batch Production Efficiency: The efficiency of batch production using SLS enables manufacturers to execute one centralized printing process. This reduces their overall production duration, particularly when handling small to medium-scale manufacturing needs.

Future of SLS 3D Printing

Do you know that Fishy Filaments based in Cornwall started a new initiative of recycling fishing nets through SLS 3D Printing? They produce high-quality nylon from discarded fishing nets for 3D printing. The major automotive firms Ford and Mercedes-Benz have expressed interest in evaluating the use of their recycled nylon from Fishy Filaments in future vehicle components.

Furthermore, in the future Selective Laser Sintering 3D printing technology will progress more because of its better materials selection, faster operational speed, and superior accuracy levels. It is projected that by 2030, the global 3D Printing market will reach USD 88281.2 million. The technology will continue to extend its range of industries through revolutionizing manufacturing and bringing more sustainable processes.

Cubein: Transforming Industries with Advanced SLS 3D Printing and Additive Manufacturing

3D printing through SLS technology transforms industries through its unmatched quality in design options, material strength and enhanced operational effectiveness. The potential of SLS 3D printing continues to expand because it enables breakthroughs in different industries from automotive and aerospace sectors to healthcare, consumer goods, and industrial manufacturing.

At Cubein, we follow innovative approaches by utilizing state-of-the-art additive manufacturing solutions. Our SLS 3D printing allows manufacturers to create quick prototypes and large scale production runs through unlimited possibilities.

| Ready to explore the potential of SLS 3D Printing?

Connect with us today! |