In today’s dynamic business landscape, where innovation is the key to success, companies are increasingly turning to contract manufacturing as a strategic approach to product development. This collaborative model offers a myriad of benefits, allowing businesses to tap into external expertise, streamline production processes, and foster innovation. In this blog, we will explore the key features, benefits, and the pivotal role played by contract manufacturing in shaping the landscape of modern product manufacturing.

The collaboration between companies and contract manufacturers has become a cornerstone for turning innovative ideas into tangible realities in this ever-changing world of product development.

In this blog, we will look into the dynamics of contract manufacturing, uncovering how it drives innovation, accelerates time-to-market, and revolutionizes the product development journey.

But first, let us understand what is Contract Manufacturing:

Contract manufacturing refers to a business arrangement in which a company (the hiring or client company) outsources the manufacturing of its products to a third-party manufacturer (the contract manufacturer). In this arrangement, the contract manufacturer is responsible for the production processes, assembly, and sometimes even the design of the product, based on the specifications provided by the hiring company.

Key Features of Contract Manufacturing:

Expertise Access:

It allows companies to leverage the specialized skills and knowledge of manufacturing experts. By collaborating with established manufacturers, businesses can tap into a wealth of experience and technical know-how, accelerating the product development lifecycle.

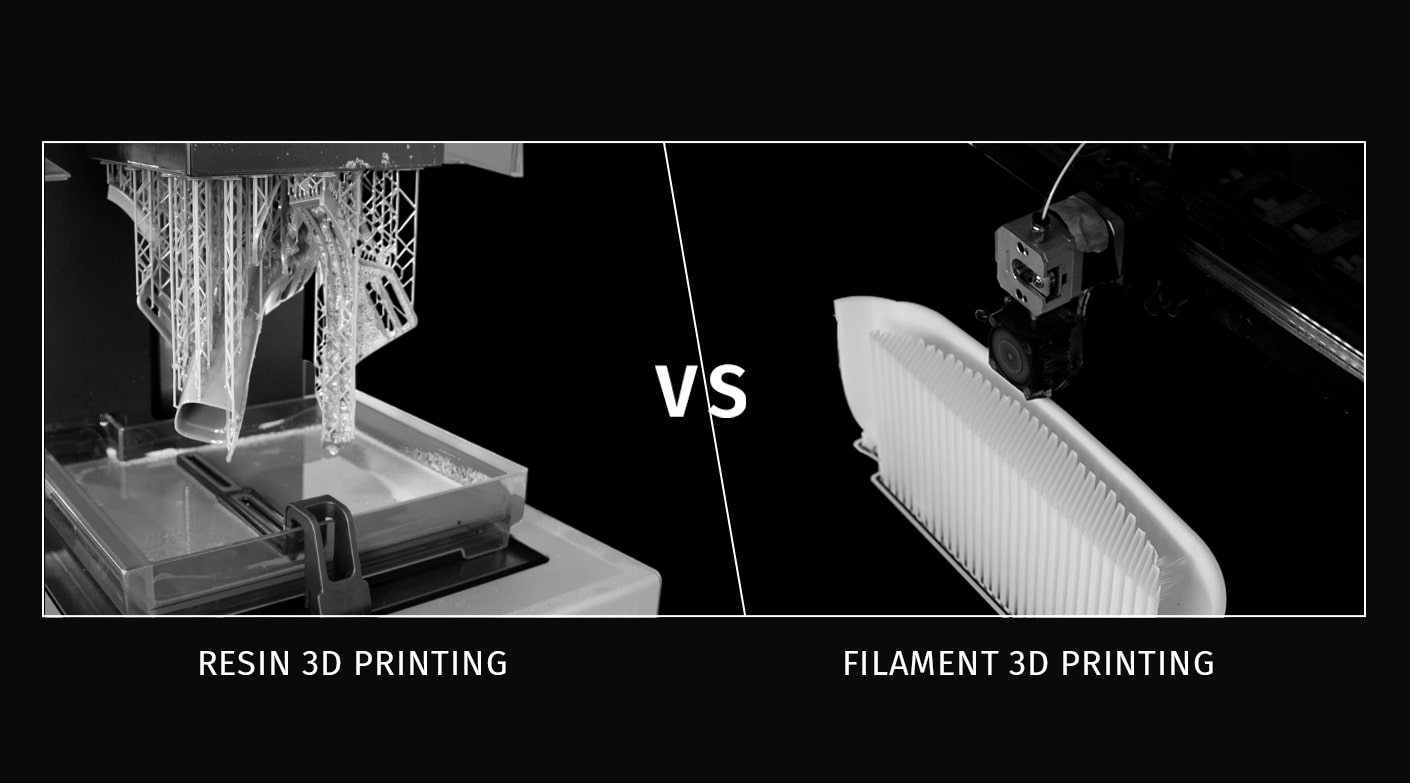

Access to Advanced Technologies:

Contract manufacturers typically invest in state-of-the-art equipment and technologies, such as rapid prototyping, 3D printing contract manufacturing, CNC machining, or injection molding. Clients can leverage these advanced technologies without having to invest in them directly.

Resource Optimization:

Companies can optimize their resources by outsourcing manufacturing processes to contract manufacturers. This enables them to focus on their core competencies such as research, design, and marketing, while leaving the production intricacies to experts.

Cost Efficiency:

It often proves to be a cost-effective solution. Businesses can avoid capital-intensive investments in manufacturing facilities and equipment, opting instead for a more flexible and scalable production model.

Flexibility and Scalability:

Contract manufacturers offer flexibility in production volumes, allowing companies to scale their operations based on market demand. This adaptability is particularly beneficial for businesses with fluctuating production requirements.

Benefits of Contract Manufacturing in Product Development:

Speed to Market:

It accelerates the product development timeline. With streamlined production processes and ready access to manufacturing capabilities, companies can bring their products to market faster, gaining a competitive edge.

Innovation Catalyst:

Collaborating with contract manufacturers opens the door to innovation. These partners often bring a fresh perspective, advanced technologies, and a wealth of industry knowledge, contributing to the enhancement of product features and overall quality.

Risk Mitigation:

The risks associated with manufacturing, such as equipment maintenance, regulatory compliance, and market fluctuations, are shouldered by the contract manufacturer. This allows the hiring company to navigate uncertainties with reduced risk exposure.

Quality Assurance:

Reputable contract manufacturers adhere to stringent quality control measures. This commitment to quality ensures that the final products meet or exceed industry standards, enhancing the brand reputation of the hiring company.

The Role & Advantages of Contract Manufacturing:

Enabling Specialization:

Contract manufacturers often specialize in specific industries or types of products. This specialization allows businesses to tap into a pool of expertise that may not be available in-house, leading to higher quality and more innovative products.

Strategic Partnerships:

Contract manufacturers serve as strategic partners, collaborating closely with businesses throughout the product development process. This partnership model fosters open communication, transparency, and a shared commitment to achieving mutual success.

Cost-Effective Production:

By outsourcing production to contract manufacturers, companies can benefit from economies of scale. Contract manufacturers often operate with efficient production processes, reducing overall manufacturing costs and providing cost-effective solutions.

Market Expansion:

It facilitates market expansion by allowing businesses to focus on marketing and distribution efforts. This enables companies to explore new markets without the burden of establishing manufacturing facilities in every location.

In conclusion, the role of contract manufacturing in product development is pivotal for businesses aiming to stay innovative, competitive, and agile. As companies navigate the ever-evolving landscape of modern business, leveraging the expertise of contract manufacturers becomes a strategic imperative, fostering efficiency, innovation, and ultimately, success in the marketplace.

Contract manufacturing is prevalent across various industries, including electronics, pharmaceuticals, automotive, consumer goods, and more. It allows companies to benefit from the manufacturing expertise of specialized partners, reduce production costs, and focus on their core competencies. The success of this arrangement relies on clear communication, well-defined specifications, and a strong partnership between the hiring company and the contract manufacturer.

If you are looking for contract manufacturing services, Cubein would be the right place that provide you with services like Rapid Prototyping, Industrial Designs, Contract Manufacturing Services, Low-volume Manufacturing, Injection Tooling & Production, etc.