3D printing technology, a part of additive manufacturing, has already changed how manufacturers produce various items. From tools and toys to machinery and automotive parts, layer-by-layer technology has the potential to create even the most complex parts for industries like aviation, automotives, defence, etc. Consumer-friendly 3D printing services in India are taking additive manufacturing to a whole new level and creating parts that are used in homes, industries, and various business verticals.

3D printing is the new-age tech that is changing how Indian product businesses and manufacturers conceptualize, design, and manufacture products. As businesses face increasing pressure to innovate quickly and cost-effectively, 3D printing, with its exceptional competencies, is the way to go. What’s more? The latest innovations in advanced tech for industrial design and rapid prototyping are further catalyzing the 3D printing industry.

This article explores how the best 3D printing services in India can revolutionize your business operations and drive growth in the dynamic Indian market.

What are 3D Printing Services?

3D printing 3D printing services construct a tangible item from a virtual blueprint. This method operates by depositing successive thin layers of materials such as liquid or powdered plastic, metal, or cement and subsequently bonding these layers to form the final object. When you hire 3D printing services in Gujarat, such as Cubein, you get access to advanced manufacturing capabilities. Also, you don’t need to invest in in-house manufacturing facilities.

What Solutions Do 3D Printing Services Offer?

| Design and Engineering

Any new product business can take the help of 3D printing services to create perfect 3D models for printing. |

Prototyping

These services assist in rapidly producing functional or visual prototypes for testing, validation, and demonstration. |

Materials Selection

3D manufacturing companies in India, such as Cubein, also advise in the selection of material & appropriate 3D printing techniques. |

| Manufacturing

Producing end-use parts or products in quantities as required by the businesses. |

Post-Processing

Finishing printed objects through cleaning, curing, machining, painting, or other treatments to achieve desired aesthetic and functional properties. |

Quality Assurance

3D printing companies test and verify that printed components meet the required specifications and standards. |

If you think 3D printed materials are fragile and break easily, you are mistaken. Today’s 3D printers are capable of building objects that defy odds and offer extreme durability. The increasing preference for 3D printing services is evident in the adoption statistics. The Indian 3D printing market is projected to reach USD 4,330 million by 2033, exhibiting a remarkable CAGR of 21.70% from 2025 to 2033. (source). These statistics reflect the growing recognition of 3D printing’s potential to transform manufacturing processes across multiple sectors in India.

Impact of 3D Printing Across Industries: Uses & Benefits

| Industry/Business | Uses of 3D Printing | Benefits |

|---|---|---|

| Automotive |

|

|

| Aerospace |

|

|

| Consumer Goods |

|

|

| Defense |

|

|

| Healthcare |

|

|

How 3D Printing Services In India Revolutionize Businesses?

#1 Accelerated Product Development

Lengthy product development timelines that require months to produce functional models don’t work in the hyper-competitive and trend-driven business environment. Companies that can come up with prototypes and basic functional models within days or weeks can beat their competitors. 3D printing compresses and shortens product development timelines. These faster services help aspiring product businesses quickly validate designs and make improvements before committing to expensive tooling or mass production. Car models that traditionally took months to build are now built within days using 3D printing services.

#2 Cost Reduction Across the Production Lifecycle

3D printing’s popularity stems from its cost-effective nature. This production method has a big impact on cost savings across a product’s life. It eliminates the requirement for costly equipment and molds, reducing the initial financial burden. This makes it more accessible for startups and small enterprises to introduce new products. Furthermore, 3D printing significantly decreases material waste by utilizing only the necessary amount for each component. On the other hand, subtractive manufacturing techniques squander more raw materials.

#3 Enhanced Design Freedom

Traditional manufacturing techniques have many limits because tools and molds can only do so much. 3D printing changes all that – it lets companies make complex shapes, hollow insides, and single-piece parts that weren’t possible before. Aerospace companies are now using 3D printing to make parts that are both lighter and stronger.

#4 On-Demand Manufacturing

Conventional manufacturing necessitates bulk orders and extended lead times. 3D printing powers on-demand production, assisting businesses in creating components only as required. This approach decreases inventory expenses and the need for storage space. For Indian businesses, 3D printing can reduce material wastage, particularly for spare parts that can be printed as needed instead of being kept in stock.

#5 Supply Chain Resilience

The pandemic revealed global supply chain vulnerabilities, highlighting the benefits of local production. 3D printing enables distributed manufacturing near points of use. In India, this reduces reliance on international suppliers while cutting transport costs and delays. Local production also lessens the environmental impact.

#6 Mass Customization and Personalized Products

In 2025, consumer tastes increasingly favor personalized items. 3D printing facilitates large-scale customization without the usual expenses linked to custom manufacturing. This technology provides competencies to companies to manufacture customized solutions. 3D printing is now the backbone of consumer products innovation.

#7 Sustainable Manufacturing and Waste Reduction

3D printing promotes sustainable manufacturing through:

- Material efficiency: Uses only needed material, reducing waste

- Weight reduction: Advanced designs minimize material use

- Extended product lifecycles: On-demand parts enable repairs

- Localized production: Lower transportation emissions

For Indian businesses, 3D printing offers sustainable operations through minimal material waste and product repairs, supporting a circular economy.

Types of 3D Printing Services We Provide:

As a leading 3D printing service in India, Cubein offers various prominent 3D printing technologies and services for different applications, materials, and precision requirements.

Businesses can revolutinize their product manufacturing with the below 3D printing services:

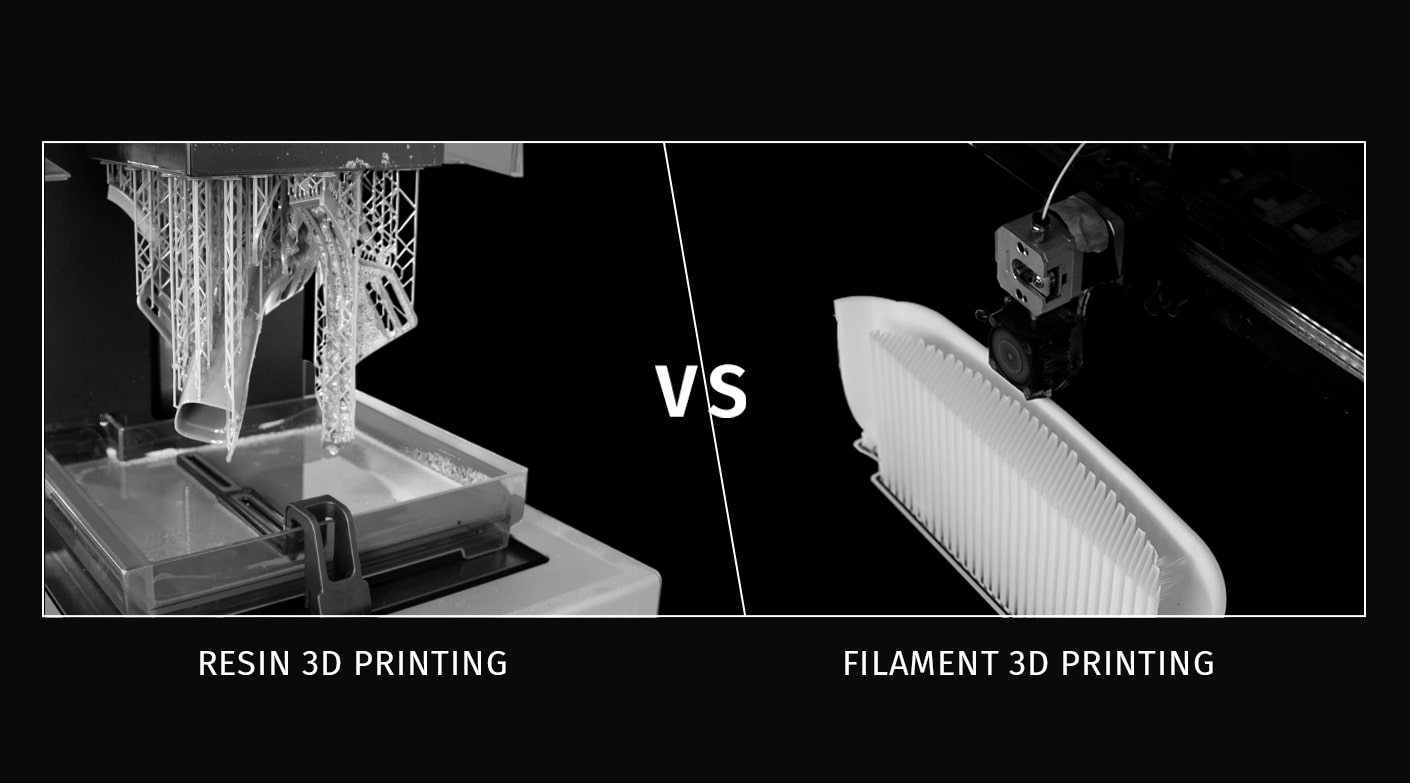

1. Fusion Deposition Modeling (FDM)

FDM technology creates three-dimensional objects by extruding thermoplastic filament through a heated nozzle, depositing material layer by layer. Online FDM 3D Printing Services are one of the most sought-after 3D printing service types.

Strengths:

- Cost-effective for prototyping

- Wide range of material options

- Easy to use and maintain

- Suitable for functional parts

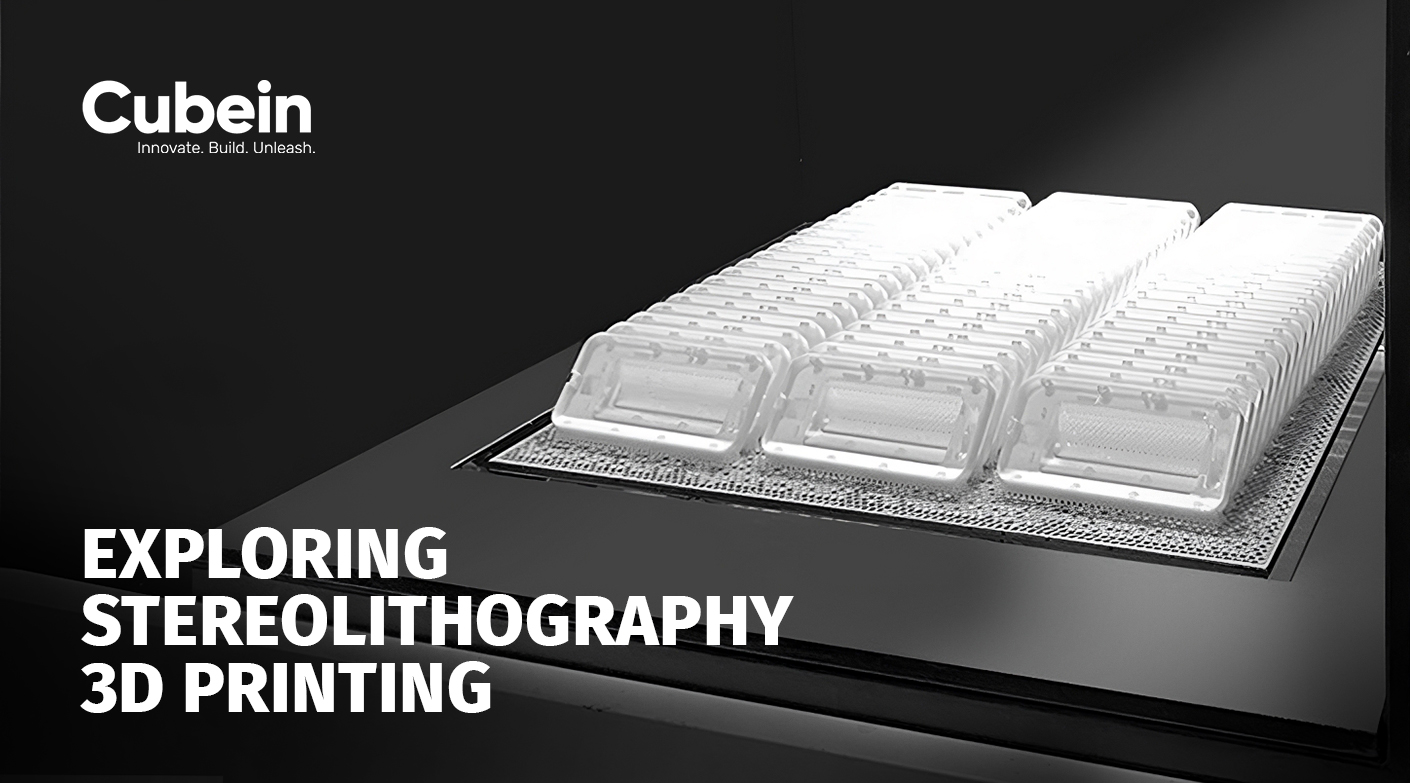

2. Stereolithography (SLA)

SLA printing methods utilize a laser to cure liquid photopolymer resin into hardened plastic. The SLA tech builds objects layer by layer with exceptional precision.

Strengths:

- Exceptional surface finish and detail

- High precision (as fine as 25 microns)

- Suitable for intricate, small parts

- Smooth surfaces requiring minimal post-processing

3. Selective Laser Sintering (SLS)

SLS technology employs a powerful laser to meld powdered substances like nylon, polyamide, or metal into solid forms. This method operates by selectively fusing the powder in a sequential layer-by-layer technique.

Strengths:

- No support structures required

- Strong, functional parts

- Suitable for complex geometries

- Good mechanical properties

4. Digital Light Processing (DLP-LPSC)

DLP technology uses a digital light projector to flash an image of each layer onto a vat of liquid photopolymer, curing entire layers at once.

Strengths:

- Faster print speeds than SLA

- Good accuracy and detail

- Consistent layer curing

- Efficiently produces multiple parts simultaneously

5. Vacuum Casting (VC)

Vacuum casting, while not strictly a 3D printing technology, often complements additive manufacturing processes by creating silicone molds from 3D printed master patterns.

Strengths:

- Excellent for small to medium production runs

- Replicates fine details and textures

- Wide range of material properties available

- Cost-effective alternative to injection molding

- Shorter lead times than traditional manufacturing

Conclusion

3D printing is a new age catalyst, a force, an innovation transforming manufacturing and business operations across India. This technology empowers businesses, regardless of their size, by providing unparalleled design flexibility, cost-effectiveness, and swift production capabilities. Quality 3D printing services in Gujarat, like Cubein, are promoting India towards becoming a global manufacturing hub.

Need to accelerate product prototyping and development and reduce manufacturing costs? Cubein’s 3D printing technologies create complex, durable parts with unmatched precision.

Request a consultation now!