Contract manufacturing has played a significant role in helping some of the biggest names across the globe to scale their production, without investing in additional resources in-house. Selecting the right contract manufacturer is a critical decision for businesses looking to outsource their production processes. This choice can significantly impact product quality, cost-effectiveness, and business success.

However, organizations are apprehensive about choosing contract manufacturers, because of apprehensions regarding the quality, way of working, and the perception of diminished control over manufacturing operations. If you find yourself in the same boat, this blog can help you cut down the noise and choose the right contract manufacturer, best suited for your business needs.

What is Contract Manufacturing?

Contract manufacturing involves the outsourcing manufacturing of end-to-end products, parts, or equipment to a third-party manufacturer. These manufacturers provide Manufacturing-as-a-Service (MaaS) to product companies that lack suitable infrastructure, tools, resources, and expertise. It is also used by companies overwhelmed with work and looking to reduce the burden on employees and resources.

In fact, global consulting firm McKinsey in their article titled “A New Growth Formula for Manufacturing in India” emphasized the potential of contract manufacturing as a core strategy for businesses to grow in global markets and fulfill overseas orders. This is because companies are operating below their potential and utilizing only 60 to 70% of their capacity.

7 Effective Ways in Which You Can Choose A Contract Manufacturer

For some third-party manufacturing might seem like losing control over the manufacturing, but growing a business exponentially involves eliminating doubt through research. Hence, companies need to consider the following areas when selecting a contract manufacturer so that they can grow their business while saving resources and money.

1. Feasibility Analysis

Tech giant Apple uses the services of contract manufacturers for some aspects of manufacturing while it is using in-house capabilities to test the use of 3D printers in producing the steel chassis for its smartwatches. Hence, each business needs to analyze its strengths, weaknesses, and what’s at stake.

Feasibility analysis is the best way to take this forward. Before choosing a contract manufacturer, analyze in-house resources and, the cost involved in adding tools, infrastructure, and labor. Compare this with the cost involved in outsourcing to third-party manufacturing companies. If you already have the resources and the infrastructure, consider the demographics and location.

Outsourcing manufacturing can sometimes be more cost-effective, even if a company has the necessary resources in-house. This happens when logistics and assembly take place at the manufacturing location, especially if the company doesn’t have a facility or base there. By outsourcing, they can avoid the high costs of transporting materials and assembling products in multiple locations.

2. Scalability, Iteration and Innovation

Choosing a resource and infrastructure-rich contract manufacturer is a prerequisite. Every business has expansion and growth as its future agenda. Whether you are a startup just testing the waters and don’t want to risk investing in-house or a rapidly evolving business without the resources/capabilities to scale or want to establish multiple growth engines, with third-party manufacturing anything and everything is possible.

Hence, when you choose these contract manufacturers you can scale up or down, according to influx.

We find contract manufacturers who not only have the technical know-how but also are ready to iterate and innovate according to your vision or change in requirements. Though getting things right the first time is the aim, a new product goes through its share of change and brainstorming.

Choose contract manufacturers like Cubein who can provide experience-based insights, collaborate with you, and bring your product idea to shape.

3. Speed To Market

Today’s cut-throat competition means getting your product to the market before your competitors do. Businesses run on quality and speed. This is where contract manufacturers with advanced tools, rapid prototyping capability, and optimum production capacity can steward growth for your business.

And this is why manufacturing giants outsource almost 70% to 80% of finished products to contact manufacturers.

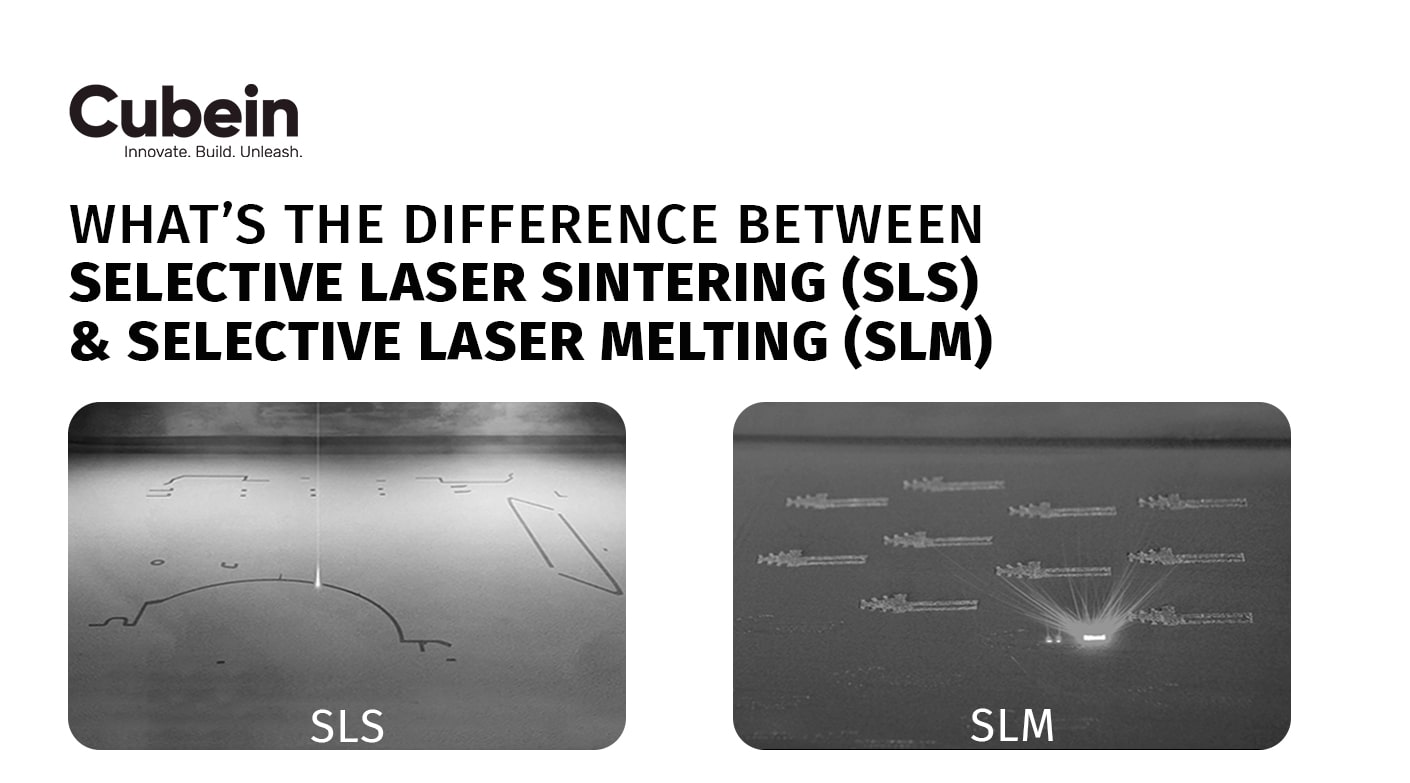

4. Expertise in Advanced Tech

The quality of products, customer testimonials, and span of foothold in the industry together demonstrate the experience and expertise of the contract manufacturers. Experienced players like Cubein, in the field of 3D and injection contract manufacturing, have specialized industry knowledge, and a deep understanding of niche sectors (e.g., automotive, defense, etc) with proven success in addressing unique challenges like compliance with industry-specific regulations.

Check whether the contract manufacturers are ahead of their time and use advanced robotics, 3D printing, or AI-driven quality control. Additionally, it is always best to prefer those contract manufacturers who have robust intellectual property (IP) protection measures. Working with such contract manufacturers adds reliability and will ensure that your proprietary designs, formulas, and innovations are safeguarded throughout the manufacturing process.

5. Global Experience

Able contract manufacturers have expertise in managing global supply chains and ensuring uninterrupted production and delivery. Additionally, they adhere to sustainability practices, and regulatory compliance and have a solid team capable of providing end-to-end project management. At Cubein we have a proven track record of bringing all our 3D printing and injection molding expertise to deliver quality work for our clients.

6. Expenses and Overhead Costs

Have a clear analysis of the costs involved in in-house manufacturing. Check the feasibility of manufacturing products in terms of labor costs, tools, resources, materials, and infrastructure. Compare these with the costs associated with manufacturing through the contract manufacturer and make a decision.

While third-party manufacturing will reduce most of the costs mentioned above, the only cost that needs to be discussed is logistics-related if the contract manufacturing company happens to be far off.

7. Technology

Companies that adopt innovative technology with time will stay relevant and be front-runners in their space. Choose contract manufacturers with next-gen machinery and tools that improve precision, speed, and scalability. Additionally, contract manufacturers that utilize Industry 4.0 technologies like IoT-enabled sensors, ML, and AI-driven production processes can help develop top-quality products at speed.

At Cubein, our additive manufacturing capabilities coupled with rapid prototyping expertise quicken iteration and testing of product designs, reducing lead times and development costs.

Wrapping Up:

3D printing and injection molding holds immense potential in the growing manufacturing sector today and the above 7 ways can help you choose the right contract manufacturer. Whereas, established global names in the fields of automotive, defense, and manufacturing are utilizing the technical acumen and expertise of expert contract manufacturers like Cubein.

Over the last decade, we at Cubein, as a fully integrated contract manufacturing company have helped companies through industrial design, rapid prototyping, low-volume manufacturing, injection tooling, production, and full-spectrum manufacturing services.

Contact us now to know more: +91 8849554035, proto@cubein.io.