Resin 3D Printing vs Filament 3D Printing: Comparison and Which One is Better for You?

Are you a manufacturing organization concerned about which 3D printing technology would be most suitable for you? Selecting between different available 3D printing options presents a challenging task. You may experience difficulties while searching for a printing method that meets your requirements. You need precision and durability in your designs, along with affordability and ease of operation.

The solution to this problem is also hidden in the 3D printing technology itself. The 3D printing services are the life-like representations of your ideas through SLA, DLP, FDM, and SLS printing systems. By carefully evaluating the various 3D printing methods available, you can find the perfect match for your manufacturing needs.

With the right 3D printing technology, you can 5X your production, reduce costs, and bring your innovative designs to life with unparalleled efficiency.

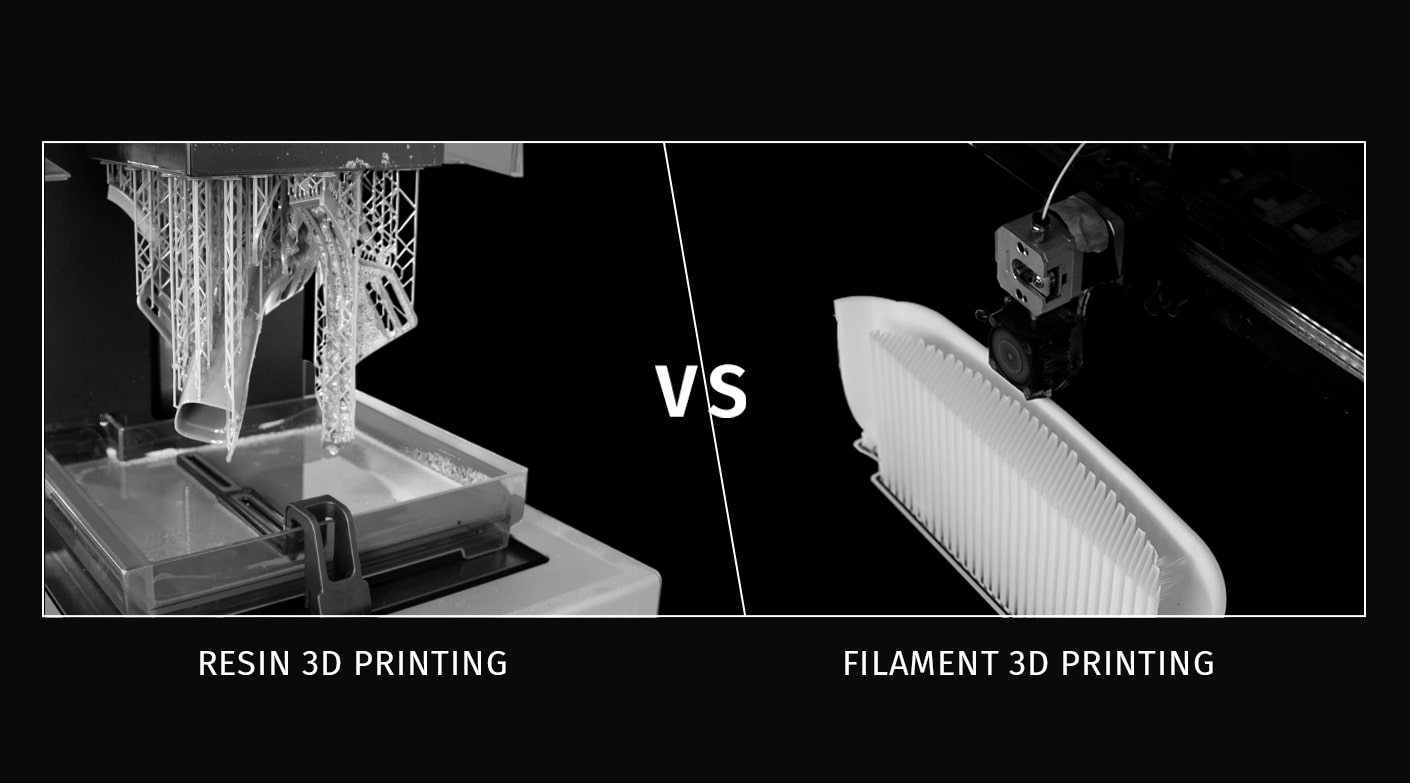

The two preferred 3D printing methods are Resin 3D Printing as well as Filament 3D Printing .

This blog focuses on the comparison of resin and filament 3D printing to help manufacturers find the most optimal choice for their applications.

Let’s compare Resin 3D Printing with Filament 3D Printing and analyze which one is better for you.

Resin 3D Printing vs Filament 3D Printing

What is Resin 3D Printing?

Creating intricate, detailed prototypes along with complex designed models represents a challenge for diverse business sectors. The production methods designed for traditional manufacturing fail to deliver adequate accuracy, economical solutions, and swift manufacturing for small-scale production.

Here’s how Resin 3D printing solves these manufacturing problems:

- The precision of resin printing reaches extreme levels because it operates at resolutions that even reach down to 25 microns. This printing is generally suitable for making miniature models, jewelry pieces, and dental apparatuses.

- The smoothness of the internal surface in resin 3D printing surpasses FDM prints because resin parts need minimal finishing after printing.

- Printable resins enable various formulations that provide customers flexibility between rigid and flexible materials. They get clear options and material compatibility generally used in medical applications, automotive industries, and artistic uses.

- Rapid Prototyping provides businesses with the capability to build accurate prototypes fast, which significantly decreases their development expenses as well as time durations.

The 3D printing process with resin material functions through Stereolithography (SLA) and Digital Light Processing (DLP). It uses a UV light for curing liquid resin in successive layers. The print technology delivers the utmost precision with its high-detail output, which fulfills the requirements of manufacturing industries.

Key Benefits of Resin 3D Printing:

- Precise results and perfect outlooks on fine-detailed models. Resin 3D printing can achieve ultra-smooth finishes with intricate designs.

- The properties of resin materials display versatility in both transparent, flexible, and strong end applications.

- Resin 3D printing is excellent for prototyping. It is ideal for detailed prototypes in art, medical, and engineering applications.

Limitations of Resin 3D Printing:

- The processing of resin models involves cleaning steps and specialized technical equipment for curing operations.

- The production costs for companies can also increase because resins and processing materials carry higher prices than filament materials.

- Resin builds optimally for smaller print sizes as its building capabilities are restricted.

What is Filament 3D Printing?

Filament 3D printing techniques (also known as Fused Deposition Modeling , FDM) is the technology that uses heated thermoplastic materials to produce solid objects by extruding and stacking material layers one by one. This technique remains popular because it provides reasonable accessibility and affordable prices to deliver sturdy objects that work across multiple applications, including prototype production, functional engineering components, etc.

Numerous manufacturing businesses encounter obstacles when they need to create affordable and scalable parts with robust prototypes. The production process of injection molding together with CNC machining is challenging for small-scale manufacturing due to its high costs and lengthy durations. Through applying Filament 3D printing, these manufacturing problems can be resolved.

Here’s how Filament 3D Printing addresses existing manufacturing challenges in the market:

- Startups and businesses operating on a small scale and strict budget find FDM printers and filament materials affordable and accessible for their needs.

- Thermoplastics composed of ABS, PETG, and Nylon align with industry standards and offer high strength and durability characteristics.

- FDM technology provides companies with a larger printing volume capacity, thereby supporting the creation of big models and sturdy industrial parts.

- This printing process has extensive material choices that can be applied to various industries because it encompasses flexible and heat-resistant abilities.

Key Benefits of Filament 3D Printing:

- The cost-effectiveness as well as accessibility of filaments allows beginners to easily use this method.

- Because of its sturdy properties, this process delivers solid functioning components for engineering and industrial uses.

- This method enables users to print big-size objects at reduced expenses as compared to resin-based printing.

Limitations of Filament 3D Printing:

- The smoothness of surfaces requires extra finishing as visible layer lines appear during the printing process at this level has low detail.

- A few disadvantages of filaments involve their lack of transparency as well as limited flexibility qualities.

- Small models (miniature objects) made through filament 3D printing tend to have a reduced quality compared to print objects from resin printing.

To learn more about 3D Printing Filaments, click here.

Which One is Better: Resin 3D Printing or Filament 3D Printing?

| Aspect | Resin 3D Printing | Filament 3D Printing | Final Verdict |

| Print Quality | The detail is high-quality, especially used in dental models and jewelry.

The surface finish is quite smooth (just like the quality of injection mold). Layer lines are barely visible. |

The detail is good but not as good as resin.

The finish of the surface can show some layer lines. The visibility of layer lines is higher but is reduced through post-processing and settings. |

You must choose Resin 3D printing if your priority is only quality. |

| Printing Speed | Speed is low because it performs layer-to-layer curing.

Batch printing is rapid if multiple small objects are printed in a layer. |

Speed is high for large objects.

Speed is varied but is less efficient from resin. |

The high-speed models in Filament 3D printing make it a winner. |

| Durability of Printed Parts | Brittle strength, specifically with standard resins.

Limited flexibility because flexible parts can be printed from standard resins. Less longevity as UV rays can reduce the strength of parts in the long run. |

More strength, especially with thermoplastics like PETG and ABS.

More flexible because of Thermoplastics Polyutherane (TPU). More durable and long-lasting. |

Filament printing is a win-win when it comes to the strength of 3D printing. |

| Build Volume | Smaller-sized volumes are built.

Limited scalability and not suitable for large items. Efficient batch printing for different small parts in a go. |

Large-sized build volumes in filament printing.

Highly suitable and scalable for large projects. Batch printing is possible but not as efficient as resin. |

If build volume and size matter, then go for Filament 3D printing . |

| Accessibility | Management is generally automated, but beginners may find it tricky to manage.

Resin printers require mandatory post-processing and include washing as well as curing. These printers have a complex learning curve, especially when you have minimal 3D knowledge. |

Management is easy because of the auto-calibration of printers.

Minimal post-processing, just some sanding is required. Filament printers have a beginner-friendly learning curve. |

If you are looking for an accessible printing solution, choose Filament 3D printing. |

| Pricing | The initial cost is typically higher.

Material cost is expensive because specialized resin items are needed. Running costs are higher due to protective gear and cleaning solutions. |

Filament printers are budget-friendly and, thus, have less initial cost.

These printers have less material costs and are cheaper. Running costs are low because of efficient flow. |

When comparing the costs of 3D resin and filament printers, Filament 3D printers come out on top for those looking to start. In a cost-effective way |

| Maintenance | Frequent cleaning is needed because resin spills are not acceptable.

Proper filtration system and ventilation is needed. |

Less frequent cleaning as there is a need to only clean the nozzle.

Ventilation is not needed unless you want to print special materials such as ABS. |

If you prefer minimal maintenance, filament 3D printers are good to go. |

Do you know that the global market of 3D printing services will reach 37.2 billion U.S. Dollars in 2026? Because of the immense growth and broad service scope of 3D printing solutions, they try to meet all your requirements, from developing prototypes with great details to designing miniatures and manufacturing durable industrial elements.

Wrapping Up

The decision to use Resin 3D Printing or Filament 3D Printing depends on your project requirements. To achieve both high-resolution and complex printing tasks, resin is well-suited. The most suitable solution between these options is filament printing because it provides durability, accessibility, and cost-effectiveness.

Your search for outstanding 3D Printing Services in Bengaluru ends with Cubein. At Cubein, we transform your creative visions into a reality. We offer premium 3D printing solutions for individual client requirements. The expertise of our company gives you access to both exact resin prints and durable models made from the filament.

- Our SLA/DLP Resin Printing is perfect for ultra-high-detail models.

- Our FDM Printing is ideal for strong, functional, and cost-effective prototypes.

- The SLS printing process delivers outstanding industrial performance because of its capability to produce durable products.

- Cubein’s Custom Prototyping & Design Services offer personalized 3D solutions for businesses and individuals.

Explore the leading 3D printing solutions of Cubein now.