Top 3D Printing Challenges and How to Overcome Them

3D printing, also known as additive manufacturing, has revolutionized industries by enabling rapid prototyping and custom manufacturing. However, like any technology, it comes with its own set of challenges.

In this blog, we’ll explore the top challenges in additive manufacturing 3D printing and how to overcome them, with a special focus on 3D printing in India and its implications for contract manufacturing and original design manufacturers in India(ODMs).

Challenge 1: High Initial Costs

The Problem

One of the primary challenges in additive manufacturing 3D printing is the high initial investment required for high-quality 3D printers and materials. While the technology has become more affordable over the years, professional-grade 3D printers can still be prohibitively expensive for small and medium-sized enterprises (SMEs).

The Solution

To mitigate this, companies can explore contract manufacturing options. By partnering with contract manufacturers, businesses can access advanced 3D printing technology without the need for significant upfront investments. This approach allows companies to leverage the benefits of additive manufacturing while spreading out costs over time.

In India, the market for contract manufacturing in 3D printing is growing, providing a viable solution for SMEs looking to enter the additive manufacturing space. Collaborating with an experienced original design manufacturer in India(ODM) in India can also help businesses optimize their designs for 3D printing, further reducing costs.

Challenge 2: Limited Material Selection

The Problem

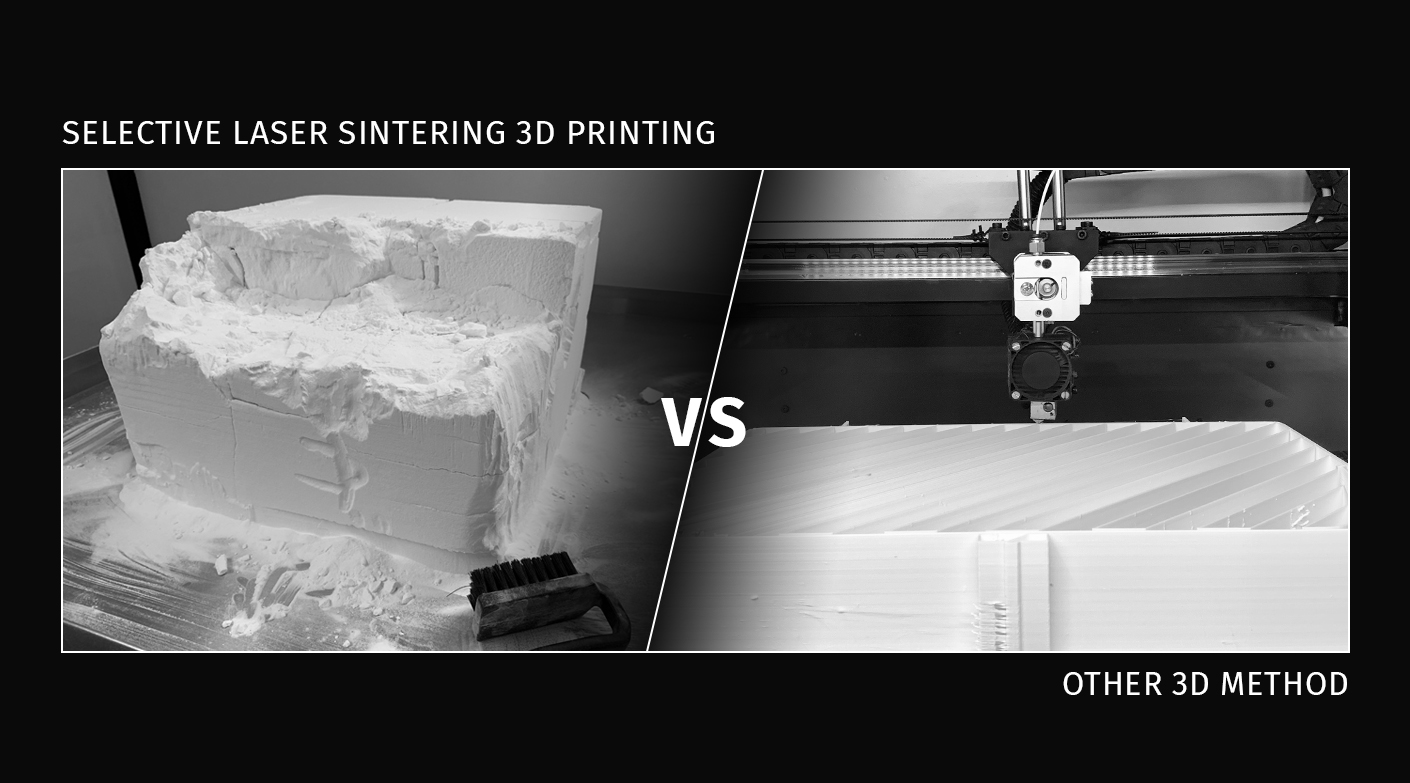

Another significant challenge in additive manufacturing is the limited range of materials available for 3D printing. Traditional manufacturing processes offer a broader selection of materials, including various metals, plastics, and composites, whereas 3D printing has traditionally been limited to a narrower spectrum of materials.

The Solution

Research and development in the field of 3D printing materials are progressing rapidly. Companies should stay informed about the latest advancements and invest in new materials that suit their specific needs. Additionally, collaborating with material scientists and researchers can help in developing custom materials tailored to specific applications.

In India, numerous startups and research institutions are focusing on expanding the material capabilities of 3D printing. By tapping into this local expertise, businesses can explore innovative material solutions and enhance their additive manufacturing processes.

Challenge 3: Post-Processing Requirements

The Problem

Post-processing is a critical yet often overlooked aspect of additive manufacturing. Many 3D printed parts require significant post-processing to achieve the desired surface finish, mechanical properties, and dimensional accuracy. This can add time and cost to the production process, reducing the overall efficiency of 3D printing.

The Solution

Implementing automated post-processing systems can significantly reduce the time and labor required for finishing 3D printed parts. Investing in advanced post-processing equipment, such as automated sanding, polishing, and heat treatment systems, can streamline operations and enhance the quality of the final product.

For businesses in India, collaborating with local ODMs who have expertise in both 3D printing and post-processing can be highly beneficial. These partners can provide end-to-end solutions, ensuring that the final products meet the required standards without extensive manual intervention.

Overcoming Challenges in 3D Printing in India

Leveraging Local Expertise

India has emerged as a significant player in the global additive manufacturing landscape. With a growing number of startups, research institutions, and manufacturing hubs, the country is well-positioned to address the challenges associated with 3D printing. Businesses can leverage local expertise in materials science, engineering, and manufacturing to overcome the obstacles in additive manufacturing.

Government Initiatives

The Indian government is actively promoting the adoption of 3D printing technologies through various initiatives and policies. Programs such as the “Make in India” campaign and the National Strategy for Additive Manufacturing are aimed at fostering innovation and supporting the growth of the 3D printing industry. Companies can benefit from these initiatives by participating in government-supported projects and accessing funding opportunities.

Training and Skill Development

Building a skilled workforce is crucial for the successful implementation of 3D printing technologies. Companies should invest in training and skill development programs to ensure that their employees are proficient in the latest additive manufacturing techniques. Partnering with educational institutions and training centers can help in creating a talent pool that is well-versed in 3D printing.

Additive manufacturing 3D printing holds immense potential for transforming industries, but it also comes with its own set of challenges. By addressing the high initial costs through contract manufacturing, expanding material selection through research and collaboration, and streamlining post-processing with automated systems, businesses can overcome these hurdles and fully leverage the benefits of 3D printing.

In India, the growing ecosystem of startups, research institutions, and government initiatives provides a supportive environment for overcoming these challenges. By tapping into local expertise and investing in skill development, companies can position themselves at the forefront of the additive manufacturing revolution.

Whether you’re a small business exploring 3D printing for the first time or an established manufacturer looking to enhance your capabilities, understanding and addressing these challenges will be key to your success in the world of additive manufacturing.