The year 2024 marks a significant turning point for 3D printing in India. No longer a nascent technology, 3D printing is rapidly transforming industries, empowering businesses, and fostering innovation.

This blog is a glimpse into what’s driving this growth and the exciting trends shaping the future of 3D printing in India.

The Rise of On-Demand Manufacturing

One of the most significant trends is the increasing adoption of 3D printing for on-demand manufacturing. This empowers businesses, particularly Original Design Manufacturers (ODMs), to produce parts and prototypes locally, reducing dependence on traditional, often geographically distant, Contract Manufacturing Services (CMS). This not only streamlines the supply chain but also offers greater flexibility and control over production schedules.

Elaborating on Key Trends in 3D Printing in India (2024)

1. 3D Printing Service in India: A Booming Industry

India’s 3D printing service industry is experiencing a surge. Here’s a deeper look at the factors driving this growth:

Meeting Diverse Needs:

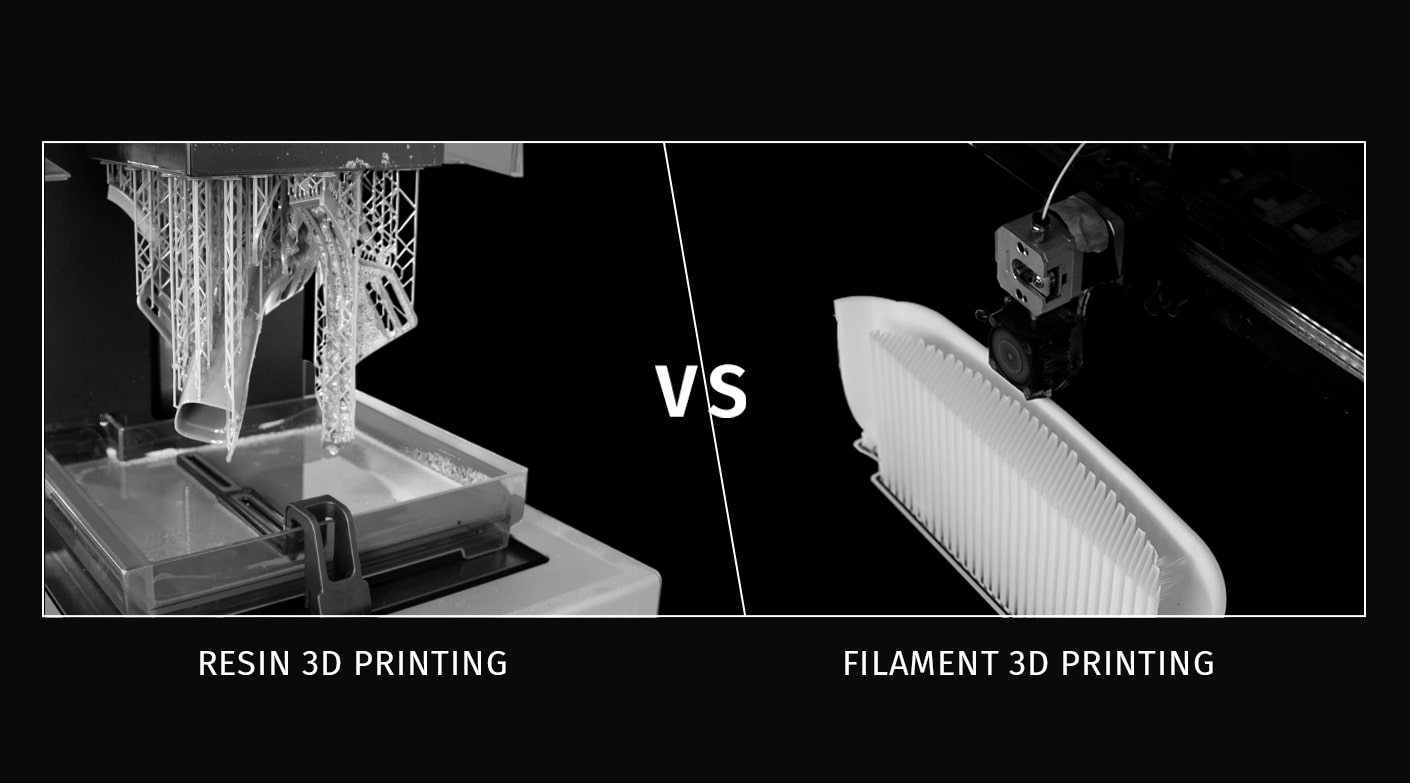

Service providers are no longer limited to basic prototyping. They’re investing in advanced printers capable of handling complex designs and a wider range of materials.

This allows them to cater to diverse industry needs, from creating architectural models for construction companies to printing custom orthotics for healthcare providers.

One-Stop Shop for Innovation:

3D printing services are becoming a comprehensive solution for businesses seeking innovative solutions. They typically offer services beyond just printing, including design assistance, material selection, post-processing (cleaning and finishing), and even logistics. This allows businesses to leverage 3D printing technology without the need for in-house expertise or infrastructure.

Reduced Reliance on Traditional Manufacturing:

With 3D printing services readily available, businesses are less reliant on traditional contract manufacturing services (CMS) located overseas. This allows for faster turnaround times, greater design flexibility, and potentially lower costs, especially for low-volume production runs.

2. Material Advancements Fueling New Applications

The development of new 3D printing materials is a game-changer:

Biocompatible Polymers:

These materials are revolutionizing healthcare. Imagine printing custom-made prosthetics, surgical implants, or even biocompatible scaffolds for tissue engineering.

High-Strength Metals:

Previously impossible geometries and lightweight, high-strength components are now achievable. This opens doors for applications in aerospace, where weight reduction is critical for fuel efficiency, and in the automotive industry, for creating lighter and stronger car parts.

Flexible Filaments:

Printing with flexible 3d printing filament materials allows for the creation of functional prototypes, customized wearables, and even soft robotics applications.

3. Collaborative Design and Open-Source Innovation

The Indian 3D printing community is fostering a collaborative environment:

Online Platforms:

Platforms connect designers, engineers, and makers, allowing them to share ideas, collaborate on projects, and access a vast library of open-source 3D printing files. This eliminates the need to reinvent the wheel and speeds up the development process.

Faster Development Cycles:

With readily available design files and the ease of customization offered by 3D printing, businesses can iterate on designs quickly and efficiently. This allows them to get innovative products to market faster.

Democratization of Technology:

Open-source platforms and online communities make 3D printing technology more accessible. This empowers individuals and startups to experiment, innovate, and contribute to the larger 3D printing ecosystem.

4. Sustainable Solutions with Additive Manufacturing

3D printing is emerging as a sustainable manufacturing option:

Minimal Waste:

Unlike traditional subtractive manufacturing, which creates significant waste material, 3D printing uses only the material needed to build the object. This reduces waste generation and environmental impact.

On-Demand Manufacturing:

With 3D printing, production can be localized and parts can be printed on-demand, eliminating the need for large inventories and long-distance transportation, which reduces the carbon footprint associated with traditional manufacturing.

Eco-Friendly Materials:

Research is ongoing into developing filaments made from recycled materials. This further reduces the environmental impact of 3D printing and promotes a more circular economy.

These are just some of the exciting trends shaping the future of 3D printing in India. As technology continues to evolve and challenges are addressed, 3D printing has the potential to revolutionize how we design, develop, and manufacture products across various industries in India.

Challenges and the Road Ahead

Despite the significant progress, challenges remain. The initial cost of 3D printers can be high, and skilled professionals to operate them are still needed. Additionally, creating complex designs and selecting the right materials requires expertise. To overcome these hurdles, training programs and educational initiatives are crucial to equip the workforce with the necessary skills.

The Future of 3D Printing in India is Bright

Looking ahead, the future of 3D printing in India is bright. With continued advancements in technology, materials, and accessibility, 3D printing is poised to revolutionize manufacturing across diverse sectors. From empowering small businesses to enabling large-scale production, 3D printing holds immense potential to transform the Indian economy. As the technology matures and costs become more competitive, we can expect even wider adoption and a new era of innovation driven by 3D printing in India.

Empowering the Future

The Indian government also plays a vital role in fostering the growth of 3D printing. By investing in research and development, promoting skill development initiatives, and creating a supportive regulatory framework, India can become a global leader in 3D printing technology.

As this technology continues to evolve, one thing is certain: 3D printing has the power to empower Indian businesses, unlock new possibilities, and shape a more innovative and sustainable future. Gain more insights regarding 3D printing from Cubein, one of India’s leading Advanced Original Design Manufacturers.