- The Future of Short-Run Manufacturing Report by MLC

FastTrack Your Production Efficiency with Low Volume Production

Low-volume manufacturing acts as a crucial link between prototyping and full-scale production, delivering immense benefits for companies.

By initially producing a limited number of items, businesses can assess market response when venturing into new territories or exploring emerging trends.

When to opt for Low Volume Production?

Low Volume Production plays a pivotal role in the creation of products that cater to a specific use case and where resource viability & optimisation is to be given precedence.

Below are a few use cases when one should consider this option:

- Launching limited edition collection

- As display & antique pieces

- Market testing of new products

- Participation in exhibitions & fairs

- As a demonstration product

- For a custom order requiring specific application

The above list is purely an indicator and not an exhaustive one, if you are still unsure if your use case would benefit from Low Volume Production,

Chat with our specialists nowTailored Manufacturing Made Easy

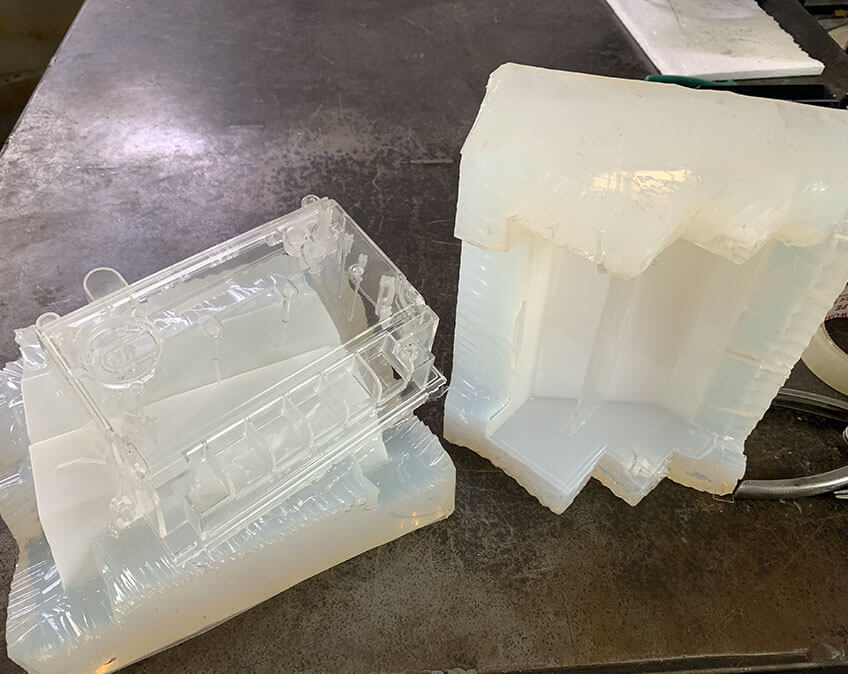

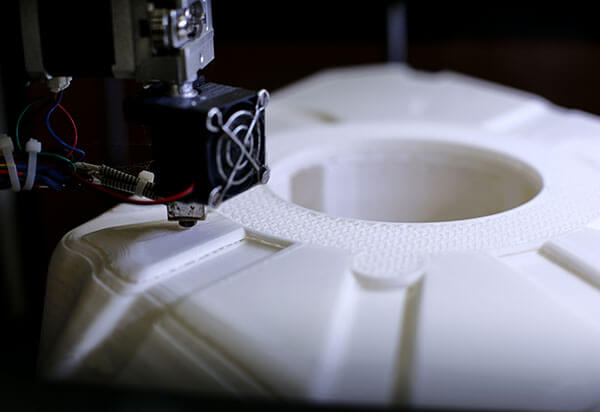

Vacuum Casting

Urethane casting or vacuum casting is the ideal solution for producing products in small quantities for marketing testing, trade fairs, display pieces, or testing new designs.

It serves as a cost-effective alternative to high-cost injection molding, utilizing various resins and silicon molds with master patterns to create intricate structures with detailed features.

Inquire Now

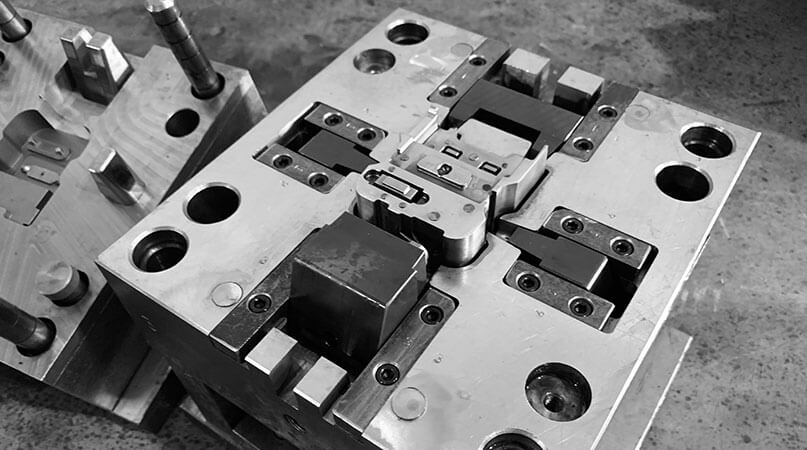

Rapid Tooling

Rapid tooling, also known as bridge or soft tooling, involves swiftly creating moulds, dies, or tooling components for manufacturing. It offers significant cost and time savings, particularly when high-quality output is needed with low quantities.

Rapid tooling streamlines manufacturing, enhancing efficiency, especially for smaller, short-batch production runs, and rapid prototyping requirements.

Inquire Now

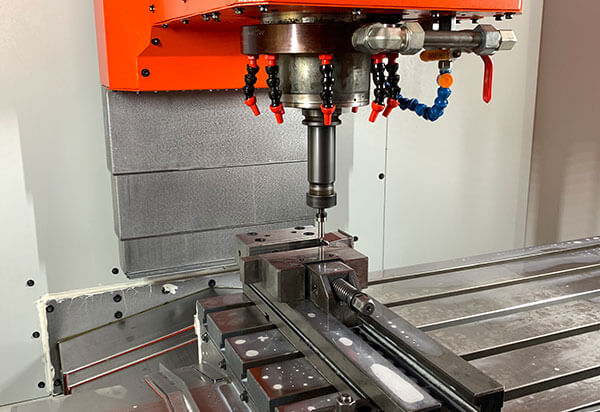

CNC Machining

CNC Machining is an automated computer controlled process whereby layers of materials are removed from base material called a blank or workpiece to give shape and finish to the final product. It is in direct contrast to additive manufacturing techniques and is a substractive manufacturing technique for creation of products.

CNC Machining is usually used in cases where high accuracy and higher tolerances are required.

Inquire NowBenefits of Low Volume Manufacturing

Market Exploration: Producing a small batch allows for testing market response and exploring new territories or trends.

Cost Efficiency: Despite potentially higher costs per unit, low-volume manufacturing can be a financially prudent approach in the long run for launching new products or revamping existing ones.

Flexibility: With rapidly evolving technology and market dynamics, starting with a smaller volume enables easier adjustments and revisions if needed.

Optimal Results: Gradually scaling up production after assessing the initial market response helps ensure maximum benefits in the current business landscape.

Tailored Support: At Cubein, our offerings are specifically designed to meet your evolving needs efficiently, providing comprehensive guidance and support to help you succeed in low-volume manufacturing.